Key Considerations When Planning Industrial Wi-Fi for AS/RS & AGV Systems

Modern factories are increasing the deployment of automated storage and retrieval systems (AS/RS)

and automatic gudided vehicles (AGVs) in their facilities to optimize production efficiency and reliability

Wi-Fi based technologies are emgerging as the most popular communication mehtod used in AS/RS

and AGV systems because they are flexible easy to implement scalable and futureproof. In this

articel we discuss some key points to consider when planning a Wi-Fi network for AS/RS and AGV

Modern factories are increasingly deploying automated storage and retrieval systems (AR/RS) and automatic guided vehicles (AGVs) in their

facilities to optimize production efficiency and reliability. This has led to an increase in traffic on factory floors and within industrial facilities. To be

able to monitor and control the AS/RS and AGV systems, as well as other moving equipment control center in these factories need

uninterrupted connectivity. Wi-Fi based technologies are emerging as the most popular commmunication method used in AS/RS and AGV.

systems because they are flexible, easy to implement, scalable and futureproof. In this article, we discuss some key pointsto consider when

planning a Wi-Fi network for AS/RS and AGV systems.

Plan Before Deploying a Wi-Fi Solution

Before you start installing Wi-Fi access pints (AP) in your facility, you must carfully plan the wireless network thatyou want to build. Some of

the key considerations when planning a Wi-Fi network for AS/RS and AGV systems include:

Evaluating the data rate and coverage required for your application is the first step in setting up a good Wi-Fi network. For example, the data

rates supportedin 802.11g networks are in the range of 6 to 54 Mbps. If the data coverage ccircle of an AP is smaller, a client device that

connect to the AP will benefit from a higer rate. In addition the data rate also depends on the transmitter power of the AP. Since a set of

network parameters may give different reuslts in different environments, overlapping the network coverage areas (circles) so that each coverage

circle overlaps with the previous one at a certain ratio can help clients, installed on moving equipment stay connected at all times. Restricting

the maximum number of clients that can connect per AP also help maintain stable connections.

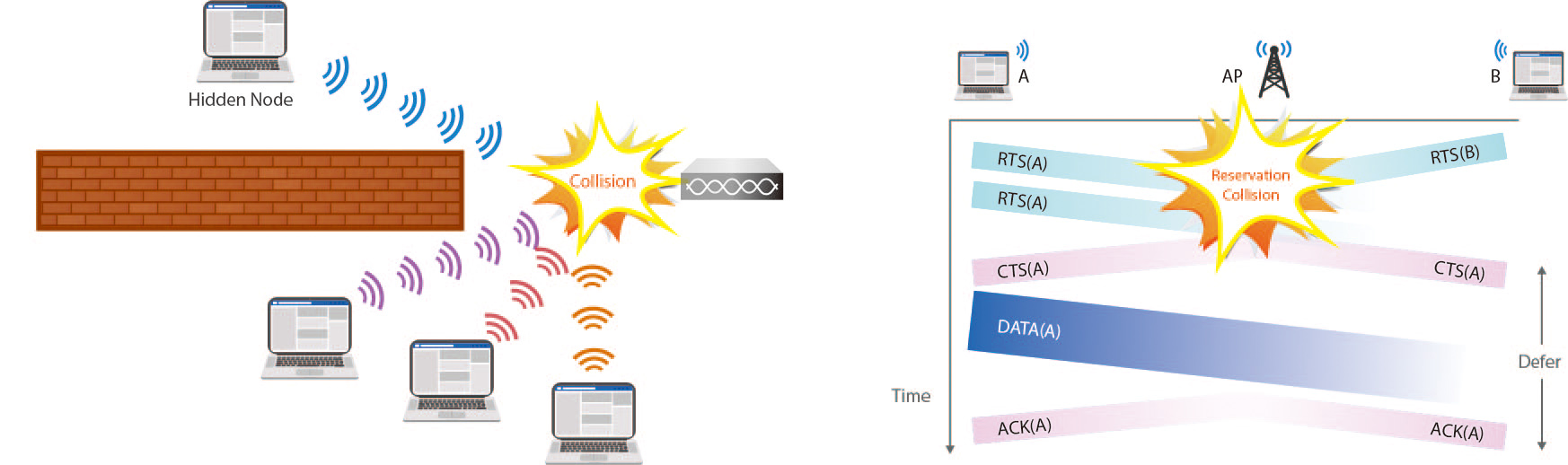

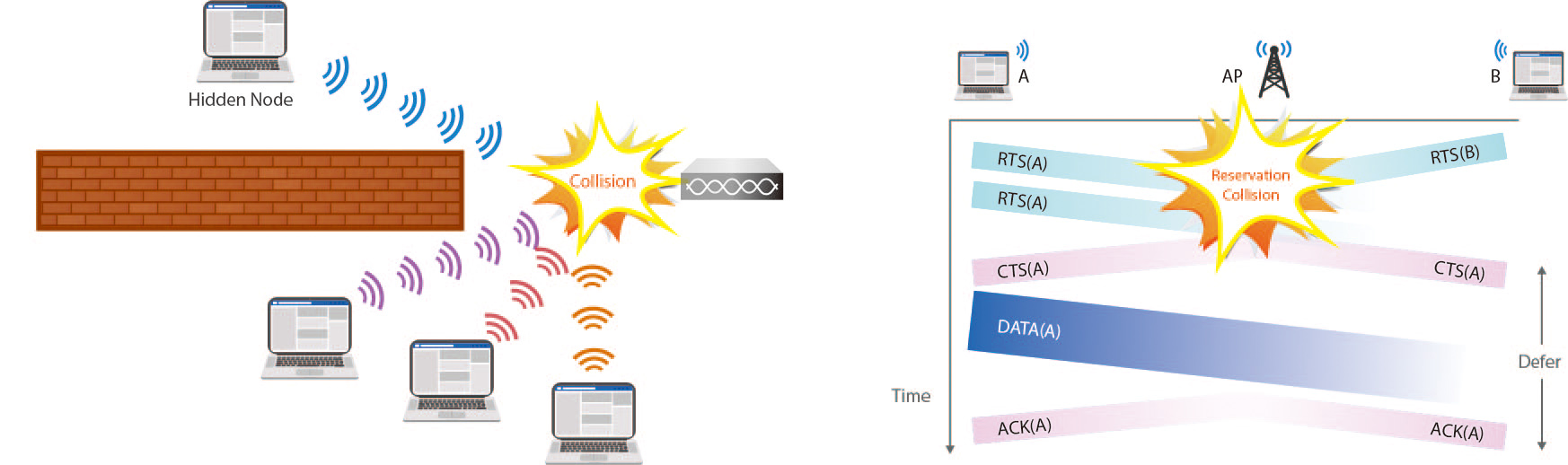

Even when the Wi-FFi coverage is good and the RF signal is storng, you may not get good throughput. Physical obstacles, such as walls, in your

factory may be preventing some APs and client from "hearing" each other, leading to the collision of Wi-Fi signals. The RTS/CTS exchange

mechnism can be used to avoid collisions between the AP and client signals

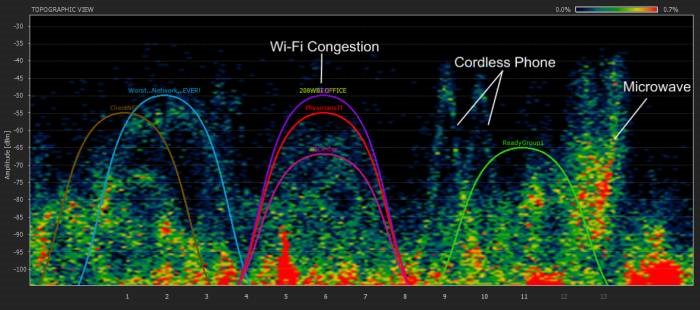

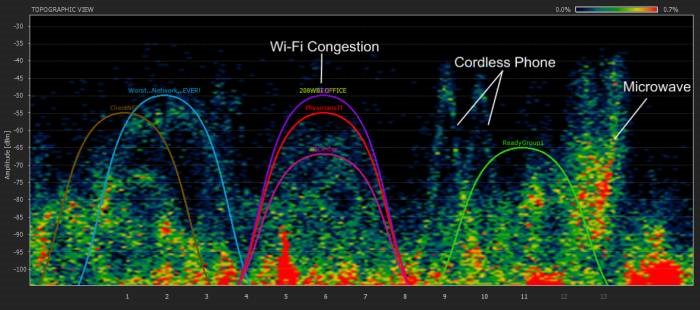

Interference is one of the key performance inhibitors in a Wi-Fi network. Interference can be of three types:

The first two types are from Wi-Fi sources. Your Wi-Fi network ca also be affected by signals from non-Wi-Fi sources such as Bluetooth

devices and microwave ovens. You should identify such sources of interference and carefully plan the location of your APs so that you get the

maximum possible coverage for client devices

Wi-Fi networks have limited coverage, which means multiples APs need to be installed to ensure full coverage in a factory or warehouse. The

Wi-Fi client installed on moving parts of the AS/RS or on AGVs must roam from one AP to another as they move aournd the facility to maintain

theconnection. Clients typically take a short roaming recovering time (3 to 5 seconds) when they roam between APs. This is not permissible in

indutrial operations because AGVs and other moving equipment will not be able to report their location to the control center during this period

The roaming recovery time should be in the milisecond range so that the clients do not disconnect from the network and can continue to report

the stauts and location of their host when they roam from one AP to another

Selecting the right antennna type of the APs and the clients installed on moving vehicles such as AGVs is a key factor in building stable Wi-Fi

networks. The main principle to be followed when installing antennas, be it on a rack structure or moving path/direction of vehicles, is to ensure

that the radiation planes of the transmitting and receiving antennas overlap at all times. This will provide adequate coverage and reliable

communication

Some AGVs operate under harsh environmental conditions, such as cold-storage warehouses where the electrical equipment need to be able

to operate at sub-zero temperatures. Therfore, it is essntial to have isolation protection at the power input and sometimes also on the antenna

ports so that electrical interference does not damage the mobile radios.

Moxa´s Solution

The AWK Series AP/bridge/client solution offers the ffollowing capabilities that can help develop reliable wireless solutions for your AS/RS andd

AGV systems.

facilities to optimize production efficiency and reliability. This has led to an increase in traffic on factory floors and within industrial facilities. To be

able to monitor and control the AS/RS and AGV systems, as well as other moving equipment control center in these factories need

uninterrupted connectivity. Wi-Fi based technologies are emerging as the most popular commmunication method used in AS/RS and AGV.

systems because they are flexible, easy to implement, scalable and futureproof. In this article, we discuss some key pointsto consider when

planning a Wi-Fi network for AS/RS and AGV systems.

Plan Before Deploying a Wi-Fi Solution

Before you start installing Wi-Fi access pints (AP) in your facility, you must carfully plan the wireless network thatyou want to build. Some of

the key considerations when planning a Wi-Fi network for AS/RS and AGV systems include:

- Evaluating the Network Capacity and Coverage Required

Evaluating the data rate and coverage required for your application is the first step in setting up a good Wi-Fi network. For example, the data

rates supportedin 802.11g networks are in the range of 6 to 54 Mbps. If the data coverage ccircle of an AP is smaller, a client device that

connect to the AP will benefit from a higer rate. In addition the data rate also depends on the transmitter power of the AP. Since a set of

network parameters may give different reuslts in different environments, overlapping the network coverage areas (circles) so that each coverage

circle overlaps with the previous one at a certain ratio can help clients, installed on moving equipment stay connected at all times. Restricting

the maximum number of clients that can connect per AP also help maintain stable connections.

- Tackling the Hidden Node Issue

Even when the Wi-FFi coverage is good and the RF signal is storng, you may not get good throughput. Physical obstacles, such as walls, in your

factory may be preventing some APs and client from "hearing" each other, leading to the collision of Wi-Fi signals. The RTS/CTS exchange

mechnism can be used to avoid collisions between the AP and client signals

- Mitigating the Effects of Interference

Interference is one of the key performance inhibitors in a Wi-Fi network. Interference can be of three types:

- Adjacent channel interference

- Co-channel interference

- Non-Wi-Fi interfference

The first two types are from Wi-Fi sources. Your Wi-Fi network ca also be affected by signals from non-Wi-Fi sources such as Bluetooth

devices and microwave ovens. You should identify such sources of interference and carefully plan the location of your APs so that you get the

maximum possible coverage for client devices

- Ensuring Seamless Roaming for Clients

Wi-Fi networks have limited coverage, which means multiples APs need to be installed to ensure full coverage in a factory or warehouse. The

Wi-Fi client installed on moving parts of the AS/RS or on AGVs must roam from one AP to another as they move aournd the facility to maintain

theconnection. Clients typically take a short roaming recovering time (3 to 5 seconds) when they roam between APs. This is not permissible in

indutrial operations because AGVs and other moving equipment will not be able to report their location to the control center during this period

The roaming recovery time should be in the milisecond range so that the clients do not disconnect from the network and can continue to report

the stauts and location of their host when they roam from one AP to another

- Selecting and Deploying Antennas

Selecting the right antennna type of the APs and the clients installed on moving vehicles such as AGVs is a key factor in building stable Wi-Fi

networks. The main principle to be followed when installing antennas, be it on a rack structure or moving path/direction of vehicles, is to ensure

that the radiation planes of the transmitting and receiving antennas overlap at all times. This will provide adequate coverage and reliable

communication

- Protecting Against the Impact of Extreme Environments

Some AGVs operate under harsh environmental conditions, such as cold-storage warehouses where the electrical equipment need to be able

to operate at sub-zero temperatures. Therfore, it is essntial to have isolation protection at the power input and sometimes also on the antenna

ports so that electrical interference does not damage the mobile radios.

Moxa´s Solution

The AWK Series AP/bridge/client solution offers the ffollowing capabilities that can help develop reliable wireless solutions for your AS/RS andd

AGV systems.

- Reliable Networks for mobile operations

- Maximum Wi-Fi coverage

- Compact Size

- Rugged Design